Please stop using Zinc Anchors in fire walls…

During our inspections, we constantly find fire walls where Zinc Alloy fixings (Shuredrives) have been used, and generally, proudly the installer declares “I used metal anchors” – well maybe so but sorry they are the wrong ones, as they may melt in a fire! That is zinc alloy fixings……not to be confused with Zinc coated Carbon steel, which are fine.

We’re asked to verify when did that came in and our understanding is it has always been the case. Historically as with many other misconceptions it was the incorrect industry standard and who knows, probably will be fine, but fire testing is done with Steel anchors (Dynabolts). Your wall system must match “as tested” to comply with the ‘deemed to satisfy’ route to compliance with the BCA.

We always recommend ALL STEEL fixings - Husk, DPZ, Dynabolts, etc or enough Power activated nails to meet kPa shear and pull out requirements. (always check with manufacturers)

One caveat to that, requirements by the Building Code of Australia, and A.S. 1170.4, which deals with the seismic restraint requirements – a huge issue at the moment and may override the above - We’ll address that in our next “Seismic what to do” article

While some installation guides are somewhat vague, board manufacturers refer to framing suppliers, who refer to fasteners companies, who refer to engineers who put it back to contractors.

So to be clear our advice is - DO NOT USE Zinc Alloy or Nylon anchors (yes we still see them) in fire rated walls or ceilings or holding up fire stopping systems.

Shuredrives are great when extra strength is needed for framing, furring channel clips etc, just not for fire rated systems or from install guide – no bulkheads

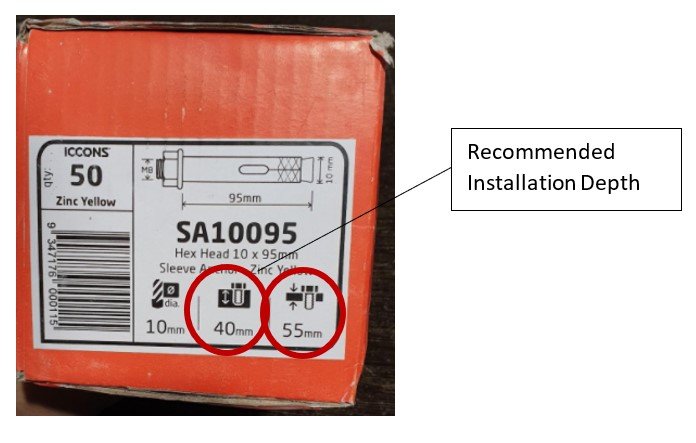

To minimise rectification costs, ensure your selection is pre approved and documented (photographs) including brand and screw depth. Always refer to the fixing manufacturer specifications on suitable fixing depths and limitations.

Below is an Extract from Promat installation guides

Husk / Anka samples

Extract from Rondo install guide

For further information, advice or certification call Plus Systems on 1800PASSIVE or email plus@plus.systems